Moreover, the involvement of suppliers and processes is higher in the State of Mexico compared to automotive industries in Spain and Brazil. Results show that the implementation level of the automotive industry is at 48.4% in the State of Mexico according to the SAE J4000 standard. In addition, this investigation shows the inferential and descriptive statistics data analysis of Mexican companies compared to the automotive industries in Spain and Brazil. The objective of this present investigation is to analyze the implementation level to the Lean System via the SAE J4000 (SAE 1999a) standard carried out among companies of the State of Mexico automotive industry. LM has been adopted in diverse industries and several countries due to its advantages in cost, flexibility and rapid response (Muslimen et al. It focuses in eliminating waste and activities that do not add value. Lean manufacturing (LM) is a management system that increases the productivity and quality in organizations. However, previous studies ranked the State of Mexico at a lower level of LM in contrast with Spain and Brazil production lines. Moreover, the involvement of suppliers and the use of lean tools in processes are higher in the State of Mexico compared to automotive industries in Spain and Brazil.

The objective of this investigation is to analyze the implementation level to the Lean System via the SAE J4000 (SAE 1999a) standard carried out among companies of the State of Mexico automotive industry.

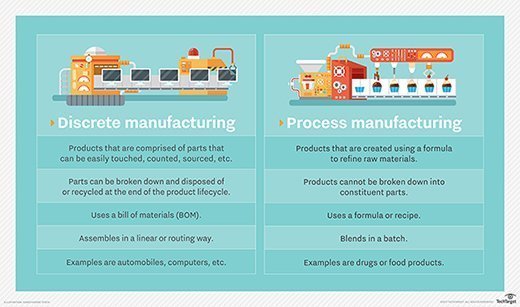

LM has been adopted in diverse industries and several countries due to its advantages in cost, flexibility and rapid response (Muslimen et al., 2013). Lean manufacturing (LM) is a management system focused on eliminating waste and activities that do not add value, with the aim of reducing costs and improving the quality and productivity of organizations. By reviewing a broad range of available academic resources, thisĬhapter mainly aims to provide a strong and thorough understanding of lean manufacturing and its importance in the modern industry. In addition, different methods of preventing or eliminating wastes are also discussed. The origin and historical background of lean manufacturing as well as the different sources of waste in manufacturing systems are thoroughly explained. This chapter describes the lean manufacturing as a fairly newĬoncept in industry. The Lean philosophies target activities that absorb resources but create no value and aim to eliminate them. Lean manufacturing (LM) is a business template that has philosophies designed to eliminate waste in the manufacturing process. Nowadays, it is broadly recognized through the industrial sectors that many manufacturing techniques which are currently implemented in fabricating products lead to production

#Manufacturing process 3 ebook series

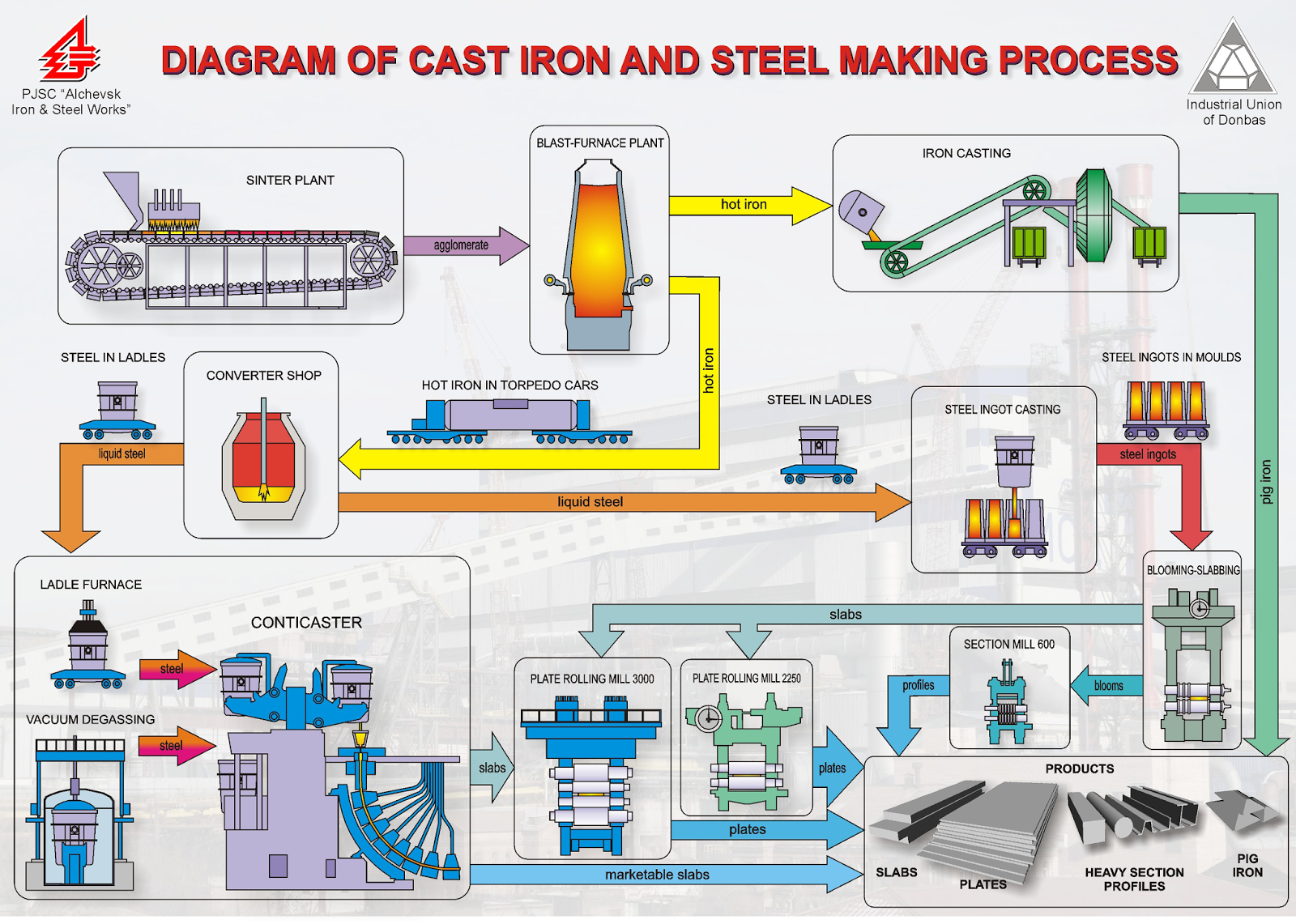

Manufacturing of parts and products regardless of their shape, geometric features and materials involves a series of processes and operations.

0 kommentar(er)

0 kommentar(er)